Item NO.:

AT-RT04Order(MOQ):

10 MTPayment:

T/T, L/C, D/PProduct Origin:

Shandong, ChinaColor:

Silver / as per customizationShipping Port:

Qingdao, ChinaLead Time:

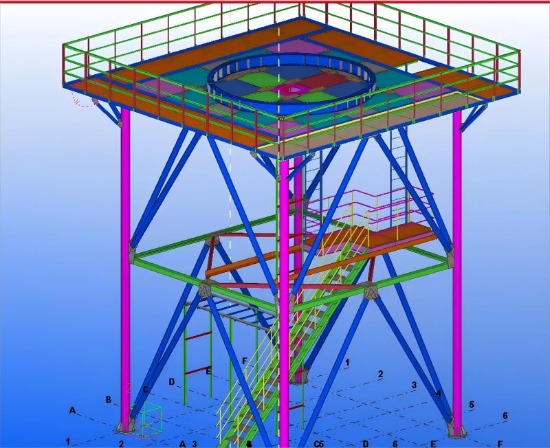

3,000 MT/ MonthLattice Framework: Composed of interconnected steel members (angles, beams, tubes) forming triangular or geometric patterns. This design optimizes strength-to-weight ratio, reduces wind resistance, and minimizes material use.

Modular Construction: Often assembled from prefabricated sections bolted or welded on-site, allowing flexibility in height and configuration.

Height: Varies based on operational needs (e.g., 30–100+ meters), ensuring unobstructed radar coverage.

Radar Platforms: Elevated platforms to mount radar antennas, often reinforced to handle equipment weight and movement (e.g., rotating dishes).

Access Systems: Ladders, staircases, or elevators for maintenance personnel.

Stabilization Features: Guy wires or cross-bracing for additional stability in high-wind areas.

Foundations: Deep concrete bases or pilings to anchor the tower, especially in soft soil or seismic zones.

Product Description:

Self supporting Lattice Tower is the most widely used in world, which has a wide range of applications, it can adapt to different antenna loads, wind speeds and topography,etc.

|

Tower Height: |

15-40 Meters (as per customization) |

|

Design Standard: |

ANSI/TIA-222-F/G/H, BS8100,Euro Part1&3 |

|

Design wind speed: |

100kph-350kph(3s gust wind speed) |

|

Exposure Category: |

B/C/D |

|

Antenna Load: |

Based on Radar with randome size and weight |

|

Galvanization Standard: |

EN ISO 1461, ASTM A153& ASTM A123 |

|

Material: |

GB/T700: Q235B . GB/T1591: Q355B, Q355C, Q355D.Q420 |

|

ASTM A36, ASTM 572, GR50. GR65.SS400 |

|

|

Surface Treatment: |

Hot-dip Galvanized |

|

Galvanization Standard: |

ASTM A123 |

|

Welding Standard: |

AWS D1.1 |

|

Welding Method: |

CO2 Shielded Arc Welding. Submerged Arc Welding (SAW). |

|

Life Time: |

More than 25 years |

|

Supply Ability: |

3,000MT Per Month |

|

|

|

Packaging Details:

Why Choose Us?

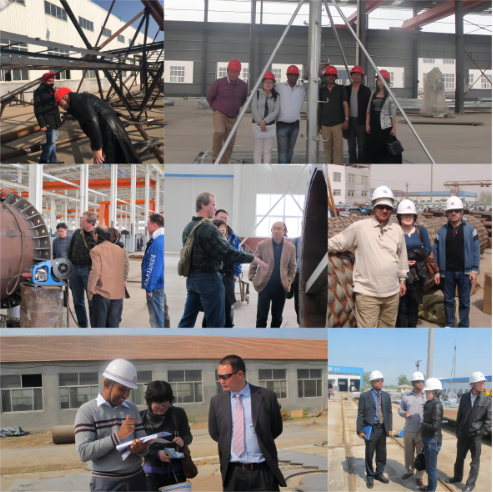

1.We have a strict quality management system and are certified to ensure that our customers will not have any problems when receiving and using the goods.

2.Imported advanced production equipment can ensure sufficient productivity and good operational stability, ensuring on-time delivery of quality and quantity for our customers.

3.Our long-term accumulation in this industry has given us a good reputation and credibility, and our high-quality products can be seen in major regions of the world.

Full Experience in the Industry

Precision Equipment

Large-scale laser cutting equipment can make the parameters of accessories on the tower smaller. Coupled with professional worker operation and technical guidance, excellence will be penetrated into each of our products.

Mature Production Line and Sophisticated Employees

Hot-dip Galvanization:

Hot-dip galvanization thickness over 100 microns, having strong anti-rust and anti-corrosion capabilities and strictly according to ASTM A123 standard.

Professional Technical Engineering Team